Gerresheimer extends cooperation with the Amberg-Weiden University of Applied Sciences

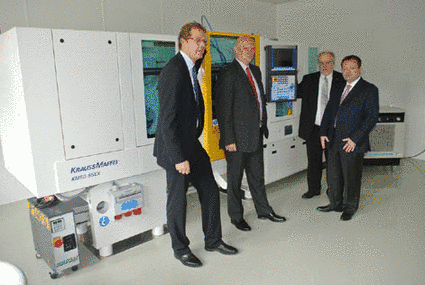

Gerresheimer Medical Plastic Systems has stepped up its collaboration with the Amberg-Weiden University of Applied sciences by helping it to set up a clean room laboratory. The laboratory was officially opened on May 21 by the university management, the department management and the management of Gerresheimer Regensburg GmbH.

The ISO class 7 clean room laboratory is 50 square meters in size. It is impressively equipped with an all-electric KraussMaffei EX 50-55 injection moulding machine, a tool for test parts and a robot system. There are also plans to set up an analytical laboratory with equipment such as an optical microscope, a gas and liquid particle counter, a filter system for particle retention and identification and a germ measurement device. Outside the clean room is a changing room where personnel can put on their clean room garments before entering the clean room. Large glass panels enable the students and interested visitors to watch work in the clean room from outside.

Gerresheimer provided the tools, the measuring equipment and an injection moulding machine for the project. It also managed the laboratory set up project. “We are trying to avoid a shortage of skilled personnel by supporting universities and providing practical training,” said Manfred Baumann, CTO of Gerresheimer Regensburg GmbH, explaining the company’s involvement. “We need competent engineers that are specifically trained for our requirements and understand our customers‘ medical terminology. That’s why it’s important that the manufacturing sector gets involved in these kinds of projects.”

The laboratory isn’t just a learning facility. It is also used for research purposes. It helps to build expertise in the particle and germ-reduced manufacturing of pharmaceutical products. The entire production chain, from injection moulding, through removal and isolation to assembly, is scrutinized for particle formation. There has been very little research into the issue of designing components to minimize particle counts until now. A cooperation between manufacturers and universities can provide us with valuable insights into this field and identify new opportunities for plastic as a medical material.

About Gerresheimer

Gerresheimer is an internationally leading manufacturer of high-quality specialty products made of glass and plastic for the global pharma and healthcare industry. Our comprehensive portfolio of products extends from pharmaceutical vials to complex drug delivery systems such as syringe systems, insulin pens and inhalers for safe medication dosage and application. Together with our partners, we develop solutions which set standards and have role model status in their respective market sectors.

Our Group realizes revenues of around one billion euros and has around 10,000 employees at 47 locations in Europe, North and South America and Asia. We use first-rate technologies, convincing innovations and targeted investments to systematically consolidate our strong market position.

Press contact

Marion Stolzenwald

Gerresheimer AG

Benrather Straße 18-20

40213 Düsseldorf

Tel: +49 211 6181-246

Fax: +49 211 6181-241

E-mail: ![]() please click

please click

Karin Strasser

Gerresheimer Regensburg GmbH

Oskar-von-Miller-Strasse 6

92442 Wackersdorf

Tel.: +49 9431 639 6140

Fax: +49 9431 79838-6140

E-mail: ![]() please click

please click