Düsseldorf/Paris, January 27, 2020. The Gx Elite vials have set new standards for type I borosilicate glass packaging. They are the result of comprehensive improvement and optimization measures in the tube draw and vial forming processes. These high-end tubular glass vials are Gerresheimers’ response to increasingly stringent customer demands and expectations on the pharmaceutical market including greater demands for patient safety. The company will be showcasing Gx Elite vials at booth B60/B64 at Pharmapack in Paris from February 5 to 6, 2020.

Extremely durable and free of cosmetic defects

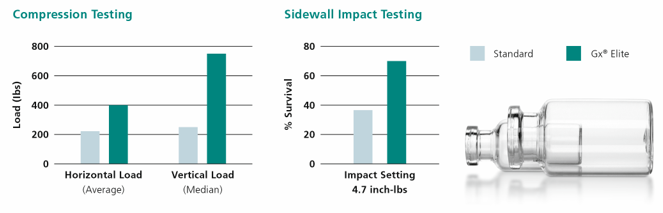

“The Gx Elite vials are the result of a quality by design approach that spanned several years. The primary focus for Elite Glass products was to provide the safest product for our customers and patients. This effort has impressed our customers,” says Hans-Ulrich Pieper, Director Sales Pharma Parenteral Solutions Europe & MENA PPG. The highly shatter-resistant vials are extremely durable, free of cosmetic defects and can be customized for specialized customer requirements. Elite Glass vials are produced using state of the art manufacturing platform with proprietary technology that creates a product that will exceed customers’ expectations. A specialized combination of design, manufacturing and handling improvements along with customized final packaging ensures that Gx Elite vials can be supplied for end-to-end improvements on all filling line applications. These types of advancements make it possible for customers to supply products to the market as needed and reduce costs for the industry, which will ultimately help everyone.