Quality management

Qualification and validation for international markets

The Gerresheimer business unit Medical Systems uses a globally standardized quality management system that is based on the ISO 9001, EN ISO 13485 and EN ISO 15378 standards and is site-specifically certified. The requirements for an environmental management system according to ISO 14001, occupational safety management system according to ISO 45001 and energy management system according to ISO 50001 are also implemented and certified on a site-specific basis. In addition, we comply with the relevant FDA guidelines, GxP and normative product requirements (such as the labeling of medical products). This also means that, in addition to the validated production processes, our buildings and clean rooms as well as the warehousing are qualified and validated in accordance with clearly defined quality criteria. For specific products, we meet additional requirement or standards in our various facilities.

Your PLUS with Gerresheimer

Validation along the entire value creation chain

Our validation approach follows the classic V model and encompasses all phases of DQ up to PQ. Each individual production process is validated in order to ensure that the total of all steps leads to the desired, process-secure production sequence. During the product origin process, the tests defined in test planning and verified during validation extending from incoming goods through process tests to approval testing are carried out by our quality planning in the Technical Competence Center in cooperation with Production. Our Quality Planning has its own quality lab in which extensive tests in the areas of material, geometry and function are carried out during all phases of the product origin process. It contains a measuring room with product-specific testing equipment for the geometric measurement of components, assembly units and finished products, a lab for material analyses and a lab for functional tests. If necessary, corresponding product tests are integrated into our highly automated assembly systems in order to ensure you the highest degree of product safety.

Systematic error processing

Our Quality Management is based on a sound corrective and preventive action (CAPA) system combined with systematic problem solving according to the Kepner Tregoe methodology. A binding change / control process ensures that changes do not have a negative effect on the qualification status of equipment or the validated status of a process.

To handle complaints and deviations, define corrective and preventive actions, and their follow up, we use an electronic workflow management system, i.e. SAP QIM, which fully meets the requirements of 21 CFR part 11. Comprehensive documentation is prepared for all quality assurance measures, which are also included in the respective customer certificates.

FDA inspection

A successful inspection by the FDA has confirmed that the Medical Systems business unit of the Gerresheimer Group occupies one of the top international positions in the production of medical technology in terms of performance and quality. The audit covers the entire value creation chain of production in our facilities.

Participation in the registration of product files

We assume responsibility for both the qualification according to GMP and FDA guidelines and the creation and submission of the documentation for medical products and pharmaceutical primary packaging materials (for example, DMF type III, EU File).

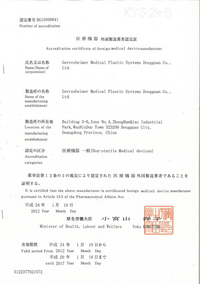

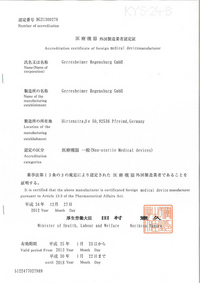

Certificate for accreditation as overseas manufacturer

In cooperation with our customers, the Gerresheimer production locations Pfreimd (Germany) and Dongguan City (China) have been accredited as manufacturers for medical products. The certificates for accreditation as "Overseas Manufacturer" in Japan are valid for five years.

Gerresheimer Management System (GMS)

We want to become better all the time, for our customers and for human health. Our key for this is GMS: Gerresheimer Management System.

In the Gerresheimer Group, the Gerresheimer Management System (GMS) provides the foundation for the continuous improvement of all business processes. GMS contains and describes the most important methods, processes and rules of a facility in a systematic and standardized form, and thus creates transparent, binding standards. Our criteria for success in terms of customer satisfaction are the goals of the GMS: Products and services of the highest quality, minimal costs, observance of delivery times, product and process innovation, correction of waste, continuous improvement, recruitment, development and retention of competence and consistent integration of all employees.