Quality

Gap-free control along the whole value added chain

Product quality is the foundation of our success. Quality management along the entire value creation chain ensures that we can meet the high requirements of our customers with regard to product quality, problem-free processability on the filling lines and a secure product supply.

Your PLUS with Gerresheimer

Certification according to international standards

Our quality management is certified according to the international standards ISO 9001, EN ISO 13485, and EN ISO 15378. Our products meet the requirements of Ph. Eur. (European Pharmacopoeia), USP (US Pharmacopoeia), JP (Japanese Pharmacopoeia), and the DIN ISO requirements for glass primary packaging material. A DMF Type III (Drug Master File) available.

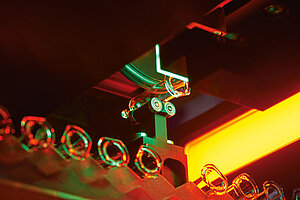

State-of-the-art camera system for 360° product inspection

Each of our production lines is equipped with in-line, proprietary camera inspection systems that have been developed internally for the inspection of geometrical parameters and cosmetic-visual defects. The result is a fully automated, 100 % visual inspection – 360° product inspection - of the entire syringe body. The cosmetic-visual inspections differentiate between cracks and scratches, particles and air pockets. All data is documented in combination with a DAQ system. Even small errors of 25 µm can be detected (diameter of a hair is 60 µm). This is only one step in our 100 % inspection system along the entire value added chain.