Post-production processing of drug delivery systems

From surface decoration to pharmaceutical filling

Our full service for drug delivery systems encompasses much more than the injection molding at a high level. It includes the processing of plastic parts in a variety of ways – optical, haptic and functional refinement extending to filling and sealing. We of course also assume responsibility for the surface decoration of all components. We refine prefabricated parts with, for example, printing, laser labeling, lacquering, metallization or sleeving. The same quality requirements apply for refinement in series as for the production of modules.

Your PLUS with Gerresheimer

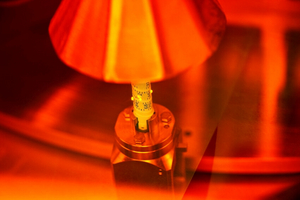

Sophisticated joining processes

For the production of drug delivery systems and pharmaceutical packaging, in addition to clean room production, we use sophisticated joining processes like the laser welding of plastic and metal parts, ultrasonic and vibration welding, as well as thermoforming and cold calking.

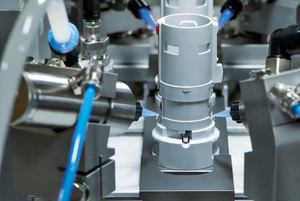

Product-specific manufacturing steps

On behalf of our customers, we assume responsibility for product-specific manufacturing steps for drug delivery systems. In the case of inhalers for example, we ensure the reliable functioning of the modules in that we improve gliding properties through the dispensing of Vaseline with individually adjustable dispensing valves in the assembly system.

Pharmaceutical packaging and filling

In order to be able to offer our customers a complete solution, which, in addition to injection molding, assembly, packaging and refinement, also encompasses loading with the drug, we have set up a pharmaceutical packaging and filling area at our Pfreimd (Germany) location. We assembled here, for example, an emergency pen for allergic reactions with an adrenalin ampoule provided by the customer. We equipped clinical samples of an applicator with a long-term implant for studies and clinical approval.

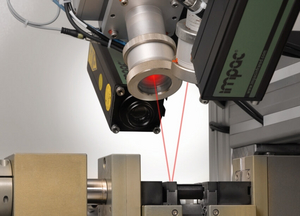

Product refinement

We of course also assume responsibility for the surface decoration of all components according to your individual wishes. We refine prefabricated parts through printing (laser marking), offset print (pad printing), metallization, lacquering, sleeving and many other decoration processes. When refining in series, we offer the same level of quality as for the production of modules: Upon request, we integrate our camera systems into the decoration systems in order to already ensure during refinement that the printed images are immaculate and that inscriptions are found in exactly the right position. In this way we realize your wish design both at a high level of quality and economically.