Gx® Prefillable Luer Lock Glass Syringes

Gx® bulk and Gx RTF® format

We offer an extensive portfolio of prefillable luer lock glass syringes that are adapted to the current requirements of the pharmaceutical industry and fulfill the requirements of modern filling systems. The prefillable luer lock glass syringes are available as bulk goods (Gx® bulk) or in „ready-to-fill“ format (Gx RTF®). Syringes can be provided as a complete system with plunger stopper, plunger rod and backstop. Various options for siliconization and printing complete our range. A Drug Master File Type III is available.

Your PLUS with Gerresheimer

Gx® bulk and Gx RTF® format

Gx® bulk prefillable luer lock glass syringes are washed, sterilized, and filled by the customer. For this form, there is a division of labor between the primary packaging manufacturer and the pharmaceutical industry where we provide the unsterilized luer lock glass syringe bodies in flat trays (Rondo trays).

Gx RTF® prefillable luer lock glass syringes are washed, siliconized, pre-assembled with tip caps or the patented Gerresheimer Gx TELC® closure systems and sterilized with ethylene oxide (EtO) by Gerresheimer Medical Systems. This means we deliver the prefillable glass luer lock syringe completely prepared for aseptic filling.

Gx RTF® syringes are packed in nests for easy handling and filling. These nests are suitable for all usual filling systems. Gx RTF® syringes are nested by:

- 100 nest (10x10) for 0.5 ml, 1.0 ml long and 1.0 – 3.0 ml

- 160 nest (10x16) for 0.5 ml und 1.0 ml long

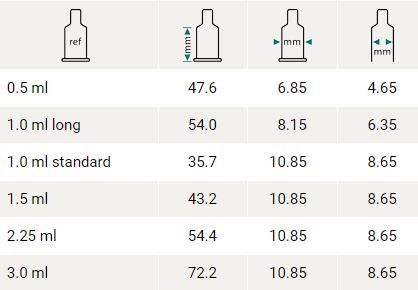

Syringe sizes from 0.5 ml to 3.0 ml (additional formats upon request)

The high-quality prefillable Gx® bulk and Gx RTF® luer lock glass syringes are produced from type I glass. The prefillable luer lock glass syringes are available in syringe sizes from 0.5 ml to 3.0 ml (individual solutions on request).

Various closure systems

Advantages Gx TELC®

- Patented integrated luer lock closure system

- Luer lock adapter with tamper-evident property

- Convenient and intuitive opening caused by soft touch surface and easy grip design

- No unintentional pop off

- Manufactured of polycarbonate (Luer Lock adapter) and medical grade Thermoplastic Elastomer (sealing cap with tamper-evident flags) using two-component injection molding

- TPE parts offer color coding of the syringe

- Insert is made of pharmaceutical rubber, formulations from Aptar Stelmi, Datwyler and West available

- Specified opening and spinning forces

- Fulfills ISO 594 requirements

- Steam-, gamma- and EtO-sterilization possible

Gx TWILC®

- TWILC = “Twistable Integrated Luerlock Closure”

- The Gx® TWILC is a screwed in Luerlock closure for the Gx® RTF 1.0 ml short, Gx® RTF 1.0 ml long and Gx® RTF 2.25ml glass syringe.

- GoTo solution regarding safety and usability, due to its rigid outer cap with an ergonomic gripping surface

- Simplicity when unscrewing the cap

- General market standard of screw caps

- Established standard in the vaccine field

Round and cut finger flanges

We offer the Gx® bulk and Gx RTF® prefillable luer lock glass syringes with round (small and standard) and cut finger flanges.

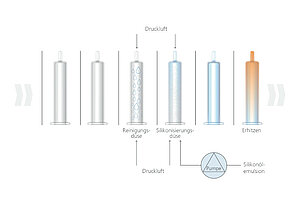

Various options for siliconization

Siliconization is critical to ensure reliable function of prefillable luer lock syringes. It ensures optimal syringe performance for delivering medications. Thanks to the hydrophobicity of the silicon layer, potential interaction between the glass and the drug formula is reduced. As a standard, our prefillable glass syringes are spray-siliconized using diving nozzle technology in order to ensure an even coating with the smallest possible amount of silicone oil. We also offer our Gx® Baked-on RTF® glass syringes, which are patented in Europe and the USA for the packaging of sensitive biotechnological medications that may interact with free silicone oil droplets. In this procedure, a silicone oil emulsion is applied to the inner surface of the syringe body and subsequently thermally fixated on the surface by heating. This significantly reduces the number of free silicone oil droplets. Despite the considerably reduced amount of silicone oil, the prefillable syringes offer reliable hydrophobic properties and especially low breakout and gliding forces that remain stable throughout the storage period.

Advantages of the Gx Baked-on RTF® syringes

- Reduced interaction risk between drug formulation and silicone oil

- Drastically reduced amount of silicone oil droplets below the visibility threshold

- Masking and inactivation of the glass surface

- Long-term stable, evenly distributed, and chemically inert lubricity coating

- Very even break loose and gliding force profile

- Ensures optimal functionality and drug formula stability over the period of medication storage

- Patented in Europe and USA

Various possibilities for printing

For the individual printing of the glass syringe body of the prefillable luer lock syringe we offer the most varied possibilities for printing such as metal-free paints, ceramic printing on glass, various designs of graduation, dose mark, various colors and other options on request.

Syringes as a complete system

Gx® bulk and Gx RTF® prefillable luer lock glass syringes can be provided as a complete system with plunger stopper, plunger rod and backstop.

Plunger stoppers

Gx® plunger rods

Gx® backstops

Syringes with reduced tungsten content or tungsten free

Metal-free luer lock glass syringes

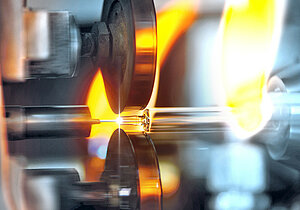

One problem associated with syringe use is that traces of tungsten or tungsten residues can leave residue behind in the bore when the syringe cone is shaped. Especially for drug products based on biotech derived drug products, our customers therefore require prefillable luerlock syringes that ideally exclude the possibility of contamination with tungsten.

With the development of an innovative production technology registered for patent, we have been able to address this requirement and create a metal-free 1 ml long Gx RTF® Luer lock syringe that is ready for series production. This process can also be transferred to other Luer lock syringe sizes at any time. The pin used to shape the cone with our new technology is not made of conventional tungsten or an alternative metal, but of a special ceramic. External studies confirm that we can manufacture residue-free luerlock syringes for the packaging of especially sophisticated medications with this new technology.

The Fresenius Institute conducted a study confirming that no ceramic residue can be detected in the syringe. A biocompatiblity study also verifies that the ceramic material is not cytotoxic.

- The pin used to shape the cone is made of a special ceramic

- 1 ml long Gx RTF® Luer lock syringe ready for series production

- The process can be transferred to other Luer lock syringe sizes at any time

- The Fresenius Institute conducted a study confirming that no ceramic residue can be detected in the syringe

- Not cytotoxic according to ISO 10993-5

Luer lock syringes with reduced tungsten

For reducing tungsten residues for standard luerlock syringes we can offer on our standard manufacturing process of syringes an additional cleaning step using a washing machine following by the forming of the glass.

Through the combination of water and ultrasonic bath, our internally developed, multi-stage treatment system thereby reduces not only the the tungsten load dramatically by 90% on average , but also brings down the load of glass particles by up to 90 percent.

Plastic syringes made of Cyclo-Olefin-Polymer (COP)

A third option is the use of plastics like Cyclo Olefin Polymers (COP) as syringe material. The production process has no potential for tungsten residuals. Our prefillable syringes of COP are therefore also exceptionally well-suited for the packaging of highly sensitive medication.

Individual solutions

Our development team would be happy to work together with you to develop a distinctive prefillable luer lock syringe made of glass which is matched to your specific agent, area of use and company brand.

Primary packaging and drug delivery system from one source

Gerresheimer Medical Systems offers the two primary materials used in the pharmaceuticals industry: primary packaging made of glass and plastics as well as customized drug delivery systems and medical devices made of plastics. Our Center of Excellence for prefillables glass syringes and glass cartridges in Bünde is working together closely with our plastic specialists in our Technical Competence Centers in Wackersdorf (Germany), Peachtree City (USA, GA) and Dongguan City (China). In this way we can combine our know-how in the areas of glass and plastics.

This gives our customers the possiblity to develop, together with our experts for glass and plastics, a distinctive syringe, an application system or a combination product which is matched to a specific agent, area of use and company brand. One convincing example of the cooperation of our experts for syringes with our specialists for plastics is our offering of plastic syringes developed and manufactured by Gerresheimer Medical Systems.

Discuss your next syringe and medical device project with our experts for syringes and plastics!

Product catalogue

You find further information in our interactive product catalogue.

Product search online catalogue