New significantly improved RTF platform solution

We are introducing EZ-fill SmartTM, the new and innovative ready-to-fill vial platform, a solution designed to improve drug packaging quality, reduce Total Cost of Ownership (TCO), and shorten lead times for customers. The new EZ-fill SmartTM is an evolution based on the standard EZ-fill® platform and it brings new advancements that drive appreciable improvements for customers amid growing demand for ready-to-fill vials.

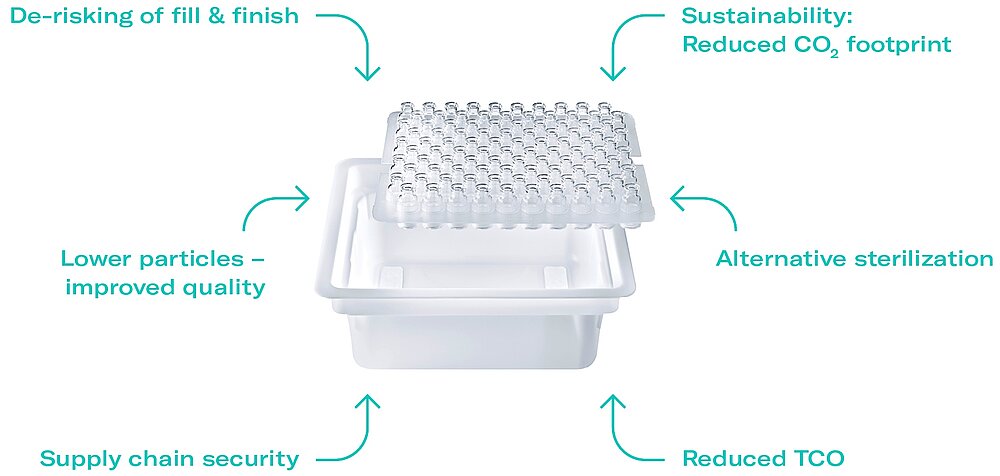

The benefits of the new EZ-fill SmartTM packaging at a glance

Lower particles – improved quality

Standard RTF packaging is typically using Tyvek cover lids. At the peel-off process particles are emitted caused by intrinsic material fibers. Thanks to the replacement of this lid with a modern polymer foil a significant particle reduction of more than 90% was achieved. This creates a new gold standard for the benefit of the patient.

Reduced TCO

Small machine footprint and centralized processing of washing / depyrogenization allows for a significant cost reduction of the fill & finish process. With the transition of these processes to us as a supplier comes also a reduced number of quality and in-process controls. In total these benefits are resulting in reduced risk and costs for the final fill & finish processing.

De-risking of fill & finish

By working with all major machine vendors for fill & finish lines we can guarantee full compatibility and thus the seamless integration into all flexible fill & finish lines.

Supply chain security

We can ensure a secured supply chain for the EZ-fill SmartTM packaging platform. The like-for-like standard of two leading global manufacturers of primary and secondary packaging solutions means a true risk mitigation.

Sustainability: CO2 neutral packaging

Gerresheimer is committed to the development of sustainable packaging solutions. Sustainability is one of our top five strategic targets. The innovative EZ-fill SmartTM packaging unleashes the potential to be made entirely with green energy and implements eco-design principles through the use of biopolymers, reusable materials and reduced weight.

Alternative sterilization

We will introduce an alternative method for sterilizing the complete RTF packaging system in parallel to the market standard EtO (ethylene oxide) sterilization. This safe and more environmentally friendly method incorporates guidelines given by regulatory bodies.