Customized Drug Delivery Systems for the Injection of Active Ingredients

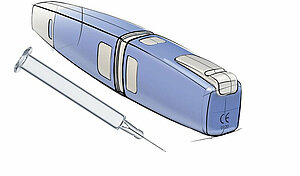

Whether glass syringes, plastic syringes (made of COP or COC), needle-free syringe systems, safety syringes or auto-injectors: Gerresheimer Medical Systems is your competent partner for contract development, industrialization or contract manufacturing of products revolving around the theme of injection.

Your PLUS with Gerresheimer

Primary packaging and drug delivery systems from one source

Prefilled syringes are increasingly being used in auto-injectors or are equipped with safety systems against puncture injuries. We have reacted to this complex requirement profile with the creation of the newly defined "Medical Systems" business unit, in which we bundle our know-how in glass and plastics. Experts from our Center of Excellence for syringes in Bünde and our plastic experts from the Technical Competence Centers in Germany, the USA, and China work together closely here. This results in syringes and auto-injectors that are optimally adapted to one another. Potential interface problems are avoided.

Tailored, customer-specific solutions: plastic syringes

We have bundled our know-how in glass and plastics in the "Medical Systems" business unit of Gerresheimer AG. The syringe experts of the Center of Excellence in Bünde work hand in hand here with the plastic experts from the Technical Competence Centers in Germany, the USA, and China. A convincing example of the cooperation is our offering of plastic syringes developed and produced specifically for the customer. Under the Gx RTF® ClearJect® brand we offer a pre-fillable plastic syringes of COP for sensitive materials.

Full Service: from the initial idea to the ready-for-sale product

Products originate from ideas, ready-for-sale solutions grow out of visions. Our range of services encompasses all stages of the value creation chain from planning to the ready-for-sale, CE-marked product: Concept development, industrial design and product development, production equipment design, mold making and special-purpose machinery engineering extending to large and small series production under FDA/GMP conditions, the assembly, as well as the pharmaceutical assembly and filling, product refinement, sterilization and packaging – at Gerresheimer Medical Systems you receive all services from one source.

Design for Manufacturing: thinking with production

Our engineers from product development, mold making and special-purpose machinery engineering work hand in hand in our Technical Competence Centers in Germany, the USA, and China. In this way we ensure the practicability of the product design in the industrial production process. The Design for Manufacturing already flows into the development phase of the injection system. How you benefit: Reduction of development time, development costs, and project risk.

Available at every point in the project: samples for clinical test studies and development

Our Technical Competence Center (TCC) in Wackersdorf (Germany) offers its own production systems (injection molding machines, project-specific assembly systems like automatic joining systems, gluing apparatus or systems for ultrasound welding), on which quick and uncomplicated production of development samples, clinical samples or small series is possible. The TCC possesses a clean room in accordance with ISO 14644-1 ISO class 8, in which the entire value creation chain can be reproduced.

Highest quality through 100% in-process inspection for surfaces and function

Our internal Automation Engineering department in the Technical Competence Center in Wackersdorf (Germany) conceives of and builds assembly systems for the highly precise separation and feed of various plastic and metal parts at the highest speed. At the same time we ensure the optimal surface quality through assembly that is gentle with the visible surfaces and visual inspection for damage to the visual parts within the assembly system. A 100% in-process inspection of the assembly steps, the assembly units and product functions parameters takes place with a large number of intelligent camera systems and inspection stations in the assembly system.

Pharmaceutical packaging and filling

In order to meet customer demand for a complete solution, which, in addition to injection molding, assembly, packaging, and finishing, increasingly includes pharmaceutical products filling, a pharmaceutical packaging and filling area has been set up at the Pfreimd (Germany) location. We assembled here, for example, an emergency pen for allergic reactions with an adrenalin cartridge provided by the customer. For clinical samples required for studies and clinical approval, we equipped an applicator with a long-term implant.

Worldwide production locations

As a global player, it is self-explanatory for us to think and act internationally. For this reason, our customers in Germany, Switzerland, the Czech Republic, North Macedonia, the USA, Brazil, and China have access to around 120,000 sqm (1,300,000 sqft) of production area, around half of which consists of clean room area in accordance with ISO 14644-1 ISO classes 7, 8, 9 and GMP-classes C and D.